What's Anode Material of Lithium-ion Battery Recycling Machine

KERUI Machinery’s lithium-ion battery anode material recycling machine is a specialized production line designed according to the characteristics of lithium-ion battery anode materials. The anode material of lithium batteries consists of lithium cobaltate powder (or lithium iron phosphate) and aluminum foil. Through processes such as shredding, crushing, and screening, the lithium cobaltate powder (or lithium iron phosphate) and aluminum are separated. The entire equipment set is designed with negative pressure to achieve high recovery rates for black mass with no dust pollution, and can be customized to the most reasonable solution according to customer needs.

Raw Materials & Final Products

Raw Materials

The raw material is the anode of lithium-ion batteries. The anode of ternary lithium-ion batteries contains lithium cobalt oxide and aluminum, while the anode of lithium iron phosphate batteries contains lithium iron phosphate and aluminum.

Final Products

The output products are black mass (containing lithium cobalt oxide or lithium iron phosphate), aluminum, and a small amount of iron.

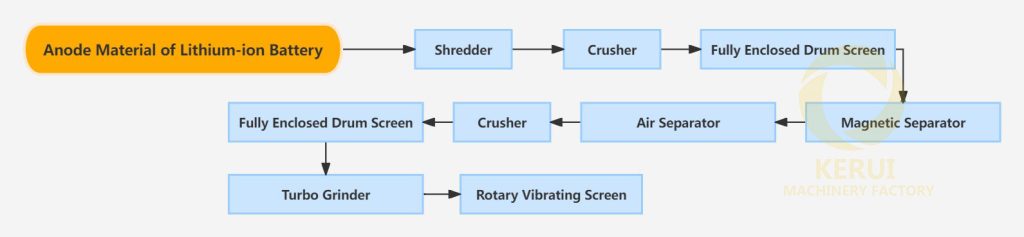

Technological Process

The anode film is processed through shredder, crusher, high-speed crusher, magnetic separator, fully enclosed drum screen, rotary screen, and other equipment to separate black mass and aluminum, achieving a recovery rate of over 99%.

Main Machines

Shredder

Shreds the anode film into small pieces

Crusher

Further crushes the shredded anode film into smaller pieces.

Turbo Grinder

Crushes the material into very small particles, increasing the recovery rate.

Fully Enclosed Drum Screen

Screens out most of the black mass

Rotary Screen

Further improves the recovery rate of black powder and aluminum in the material

Magnetic Separator

Separates out the iron content in the material

Technical Parameters

| Model | Capacity |

|---|---|

| KR-Q400 | 300Kg/H |

| KR-Q600 | 500Kg/H |

| KR-Q800 | 1000Kg/H |

| KR-Q1000 | 1500Kg/H |

| KR-Q1200 | 2000Kg/H |

Note: KERUI Machine’s anode material of lithium-ion battery recycling machine is a customized solution. The data in the table is for reference only. For detailed technical parameters and production line configurations, please consult us.

| Technical Standards | ||

|---|---|---|

| Recovery | Black mass | 99% |

| Aluminum granules | 99% | |

| Purity | Black mass | 99% |

| Aluminum granules | 99% | |

Why Choose KERUI

Service One

KERUI MACHINERY has years of experience in the field of recycling scrap metals, with superior design capabilities and after-sales service.

Service Two

KERUI MACHINERY's lithium-ion battery recycling equipment adopts a negative pressure design, resulting in higher recovery rates and no dust pollution.

Service Three

The majority of lithium-ion batteries can be recycled using our equipment without the need for manual disassembly.

Service Four

The entire production line is controlled by PLC, making operation convenient and saving labor.

Service Five

We promise a one-year warranty for our equipment, excluding consumable parts.